Bearing Isolators

Functioning:

Bearing isolators are used to protect bearings against dirt and contaminants and to improve lubrication. They increase reliability of equipment and reduce wear on interior joints.

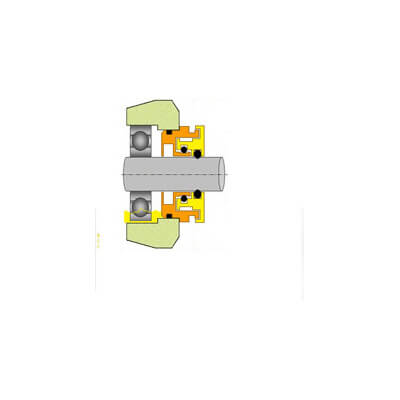

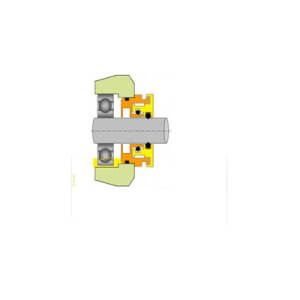

The bearing isolator is made of two parts – one fixed part, mounted on the housing, and another rotating part, fitted on the shaft. The shape of the static part makes the lubricant remain in the interior and return to the bearing casing.

Exterior contamination that attempts to get in is deposited in the dynamic zone and due to the centrifugal force and gravity it is expelled via a drain situated in the lower part of the labyrinth.

Benefits:

• Constant protection for bearings.

• Prevents contamination by vapours that is produced when the bearing casing heat up and cool down.

• Its design facilitates fitting.

• It is not necessary to carry out any form of maintenance on the piece.

• It does not consume energy.

Features:

• Standard material: Standard material: Bronze. On request it can be manufactured in other materials such as stainless steel, aluminium, PTFE.

• Temperature (elastomers): From -37 to +240ᵒC.

• Pressure: 0 bar.

• Velocity: 10.000 rpm.

It can be adapted to different shaft sizes: from 16 mm to 1200 mm.

Applications:

• Pumps, Motors and Gearboxes.

Newsletter

Egaleo 14, Piraeus, 18545

T: 210-4080022

F: 210-4080023

E: info@trms.gr